What Is The Best Sliding Gate Motor?

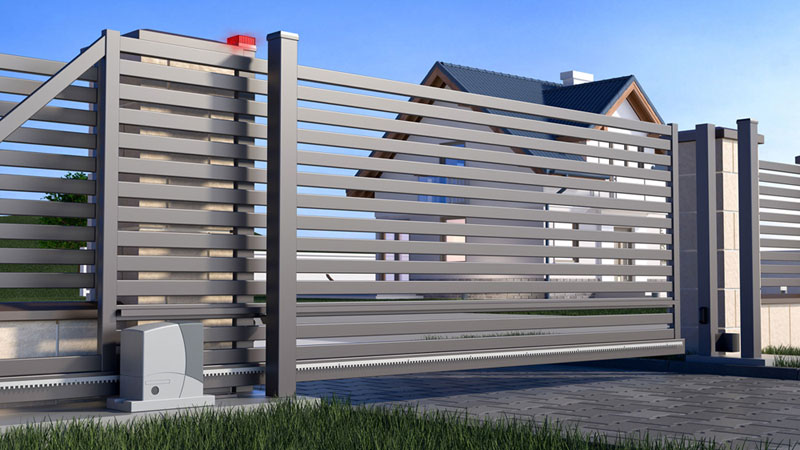

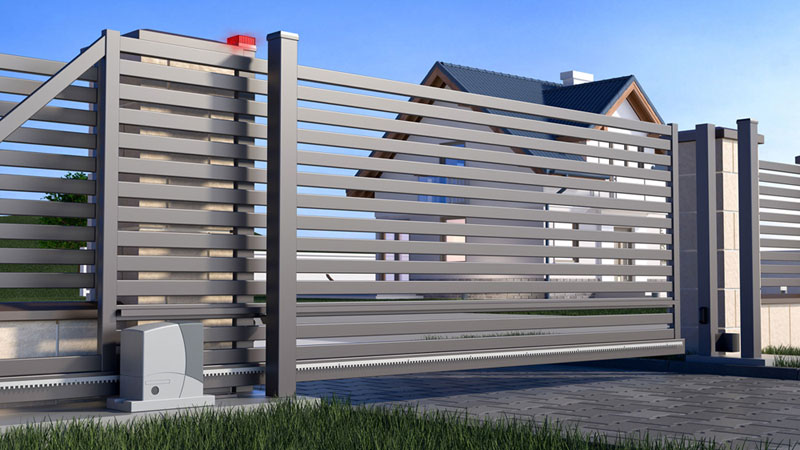

Sliding driveway gate motors are used to open and close sliding driveway gates at the touch of a button. They are reliable, robust and relatively simple so they can provide years of trouble-free electric gate use with minimal servicing.

But there are many manufacturers who make motors for automatic sliding gates. So, how do you choose which is the best opener for your installation?

The following article explains how sliding gate openers work, what the differences are and why one opener is more suited to your needs more than another.

If you’re considering having an automatic sliding gate installed or you can’t have swing gates and need to know what your options are, this is the perfect place to answer all your questions.

What Are Sliding Gate Motors?

There are two main types of sliding gate. There are ones that run on tracks, or cantilever gates that don’t need tracks.

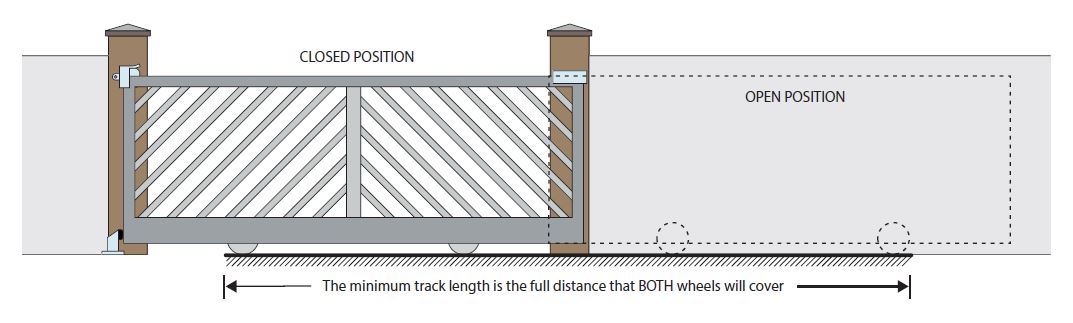

Both slide across the entrance to a property into a space on one side that must be long enough to accommodate the full length of the gate.

A sliding gate motor is used to open and close these gates automatically.

Tracked Sliding Gates

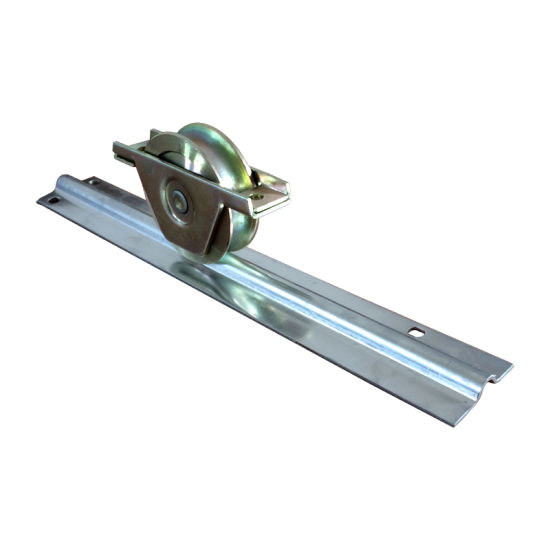

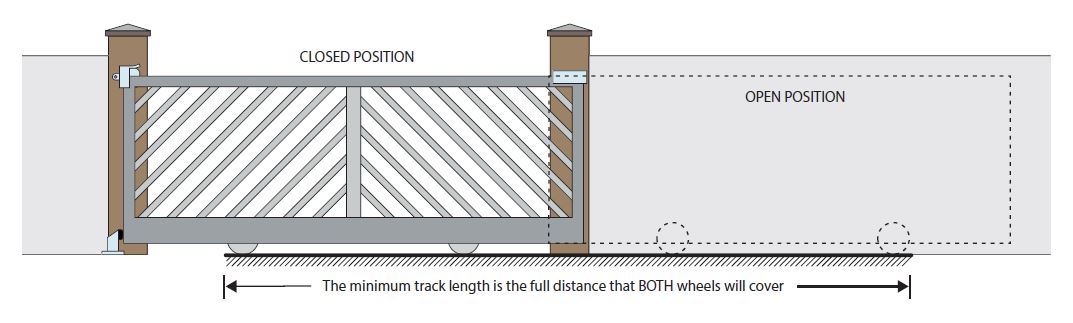

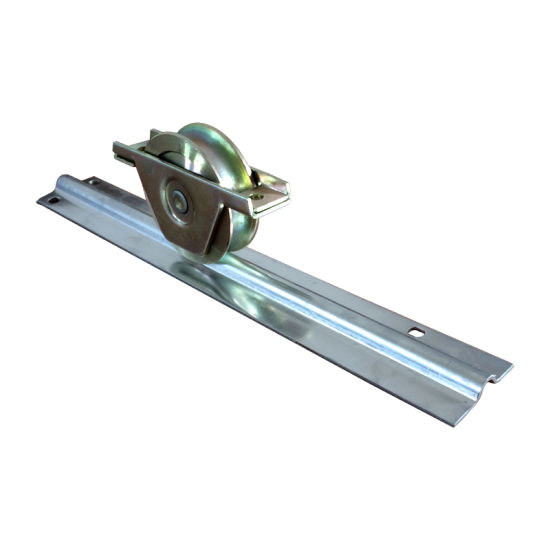

A tracked sliding gate sits on wheels which run along a track laid across the entrance to your drive.

A toothed rack is mounted along the full length of the inside of the gate. The opener is mounted inside the automatic gate by one of the posts or pillars. It is secured in place on the ground or a suitable solid platform so it can’t move.

The motor output shaft usually has a toothed cog mounted on it. The motor is installed so that the cog meshes with the rack.

To open the gate, the electric gate motor operates and turns the cog which pulls the gate open. To close the gate, the cog direction of rotation is reversed. In some circumstances, the cog is replaced with a gear that operates the gate with a chain instead of a rack.

Cantilever Sliding Gates

A cantilever gate is supported off the ground on rollers in supports installed near the motor and further away from the gate opening on the same side as the motor. A third support receives the gate as it reaches the end of its closing cycle on the opposite side of the gate entrance.

As the gate slides off this support as it opens or during the time it is closing before it reaches this third support, the weight of the automatic gate is supported entirely by the two supports on the motor side of the gate entrance.

This means that cantilever gates need to be longer than tracked gates to include a counterbalance section. This inevitably means that cantilever gates need more space to one side of the entrance than a gate that runs on a track.

The gate opener is mounted in the same way, as for tracked gates and the cog and rack method of moving the gates remains the same.

General Features

For remote control gates that run on tracks, a support at either side of the entrance holds the gate upright as it slides open and closed. Stops at either end of its travel ensure it can’t slide off the track.

In most cases, a sliding gate is a single gate. Tracked gates will cover most domestic driveways as long as there is suitable space for the gate to one side of the drive when it is fully open.

Gate And Garage Door Opening With Remote Controls

Controlling automatic gate and garage door opening is usually carried out using hand-held remote controls. At the press of a button, a remote control sends a radio signal to the receiver in the automation system and instructs it to open.

Pressing the button on the remote control again instructs the gate to close although an auto close function can also be programmed to auto close it after a set period of time. Remote controls are small enough to be kept in a pocket or bag and each remote control is programmed to the associated automation system.

With any function of an electric gate that is not initiated or controlled by a person, safe gate use is crucial. As an example, where an auto close function is used, the installation must operate with detectors to prevent impact with anyone or anything. Remote controls allow human intervention if there's a risk of injury or damage but if they're not there or their remote controls don't work for any reason, additional safety features are vital.

Other forms of remote control include intercom systems, pushbuttons and keypads.

It is also advisable to include a manual release system to release the gate motors in the event of a power failure or breakdown.

Where Space Is An Issue

Where there is not enough space to one side of the entrance for the gate to slide into, the alternatives include bi-parting sliding gates and round the corner gates. Each of these requires less space on either one side of the entrance or both sides than a single tracked slider.

Bi-Parting Sliders

Bi-parting sliders are two gates that slide together to meet in the middle of the drive. Each section then slides to its own side of the driveway when opened. In this case, a sliding gate opener is needed for each gate leaf. However, as two leaves cover the full width of the drive entrance, just over half the space of a tracked single slider is required on each slide.

Telescopic Sliders

Telescopic sliders use overlapping sections that slide closed alongside each other.

The section nearest the post is driven by a sliding gate motor and a series of cables controls the movement of the other leaf or leaves.

Round-The-Corner Sliders

Round-the-corner gates are made up of a number of narrower sections of gate assembled to make the full width. These are joined by hinges, at the top and bottom, to their neighbours. In this instance, as the gate segments can pivot vertically against their adjacent sections, the automatic gate can slide along a curved track.

Where walls and other obstacles prevent the installation of a standard sliding driveway gate, a round-the-corner gate can open into a position that is perpendicular to where it started when closed.

A round-the-corner gate is usually a single gate so only needs one operator. This is also an installation where a gear and chain drive is preferable over a cog and rack.

Unlike the range of automatic gate motor types available for automating swing gates, sliding gate openers all work the same way and all look very similar. A protective case houses the motor and gear mechanisms.

The base of the gate opener will have mounting holes for bolting it in place, and a toothed cog (or gear) mounted on the motor output shaft protrudes from one side of the motor casing.

Differences From Swing Gate Openers

As a swing gate opens it move through an arc so the way a swing gate opener works is quite different from sliding gate motors. A swing gate operator typically connects to the automatic gate via an arm or ram. To open the gate, the arm is rotated or the ram is extended.

Swing gates require more space to move through as they open and can be affected by strong winds in some circumstances.

What Different Types Of Sliding Gate Motors Are There?

Automatic gate openers for a gate that slides open all work the same way, are all constructed similarly and don’t differ considerably in appearance. Differences between individual motors exist in their power output and how frequently they can be operated each day.

Gate Length And Weight

Electric gate openers that are designed to operate a gate weighing more or that is significantly longer than another need to be much stronger and have stronger internal mechanicals. They need the power to overcome the inertia of the larger and heavier gate on start-up and slow down.

Why Slopes Are An Issue

A sliding gate should always move horizontally to avoid overloading the motor. If a driveway slopes across its entrance, a track would run at an angle. This means that the electric gate would run downhill in one direction and uphill in the opposite direction.

Pushing the gate uphill makes the gate opener work harder than it should. But an electric gate that runs downhill is potentially dangerous as there is only the connection to the gate opener preventing it from accelerating downhill.

In these circumstances, if a sliding gate is essential, a cantilever gate can be used. This type of electric gate doesn’t run on a track so it doesn't rely on contact with the ground and can be used for sloping or uneven driveways. The same type of gate opener is used and there is no need to lay track.

Gate Opening Frequency (Work Cycle) And Voltage

An automatic gate opener that needs to operate an electric gate in a commercial environment is likely to be in use much more than a motor for a domestic gate. At home, a gate may be opened a few times in the morning as the residents go to work and take children to school.

There may be a few times it is operated during the day but the next busy period for the gate opener will be in the late afternoon and evening when everyone comes back from school and work.

In commercial and industrial installations, the gate opener is likely to be working all day as deliveries are made and workers, customers and suppliers visit.

How Is Duty Cycle Determined?

The work cycle of a sliding gate opener is determined by the amount of heat the motor produces in use. All motors generate a degree of heat and this can build up and damage the motor.

If a sliding gate opener reaches a predetermined temperature, the motor will stop operating to prevent damage, and allow it to cool down.

Typical Duty Cycle For Different Voltage

The duty cycle of an automatic gate operator is affected by the Voltage it runs at.

230V gate openers will typically have a duty cycle of 30% giving them the ability to perform between 20 and 30 cycles per hour.

24V gate openers with intelligent operation will have a duty cycle of up to 80%. This means that they can perform over 50 cycles per hour.

Both 3 phase 400V and 230V inverted to 3 phase gate openers will also have a duty cycle of 80%.

So, the variations in sliding gate opener type will be obvious in the size of the motor housing and possibly the cog. Where they must operate larger gate leaves, a large motor is required. But this is probably the only obvious difference in the appearance of a gate opener other than styling cues unique to each manufacturer.

What Is The Best Type Of Sliding Gate Motor?

The best sliding gate opener for any particular installation will firstly be determined by the size of the leaf, then how often it will be used. Finally, the complexity of use and level of security required from the system needs to be considered and how these impact on costs. More complicated usage requirements will require more advanced electronic controls which will increase the price.

Installation

The chosen installer may have a preferred manufacturer whose automation equipment they are more familiar with. As most manufacturers of gate openers will make a range suitable for different gate sizes and user requirements, this is not a limitation in most cases.

It can also be a benefit, as an installer who regularly chooses one or two manufacturers’ automatic gate motors should be experienced in their installation and servicing and can troubleshoot any issues encountered during installation and daily operation of the gate opener.

Some brands are geared towards the domestic market and some cover both domestic and commercial applications with a wider range. But due to the single design of automatic gate opener used for sliders, choice is not affected by the same factors experienced by anyone selecting from the different types of swing gate opener.

Top Quality Sliding Gate Openers

The following list of automatic gate openers we recommend is not meant to be exhaustive and only describes motors for automating sliding gates that we know do the job well, are reliable and economical to run and look after.

By only listing the following doesn’t mean that we don’t recommend any not listed. It simply means that we don’t have space to list more. Having said that, our recommendations are all highly accomplished motors for carrying out the business of operating automatic gates.

Residential Installations

For single or small residential applications where the gate is unlikely to have a maximum weight over 600Kg.

For these types of applications we would recommend the following motors:

• For a maximum gate weight of 400Kg

• 230V ac

• Duty cycle is approximately 15-20 cycles per hour

• Safe working via an encoder, current monitoring and additional infrared photocells

• Simple control panel programming.

Photocell and safety edge inputs are included in all of the following.

• For a gate weighing up to 400Kg

• 24V dc

• Solar power option

• Duty cycle is approximately 50 cycles per hour

• Safe operation via an encoder and current monitoring.

• Simple panel programming and more sophisticated programming via optional Oview programmer

• Backup battery option.

• For a gate weighing up to 500Kg

• 230V ac

• Duty cycle is approximately 15-20 cycles per hour

• Safety via obstacle detection via encoder.

• Simple programming.

• For up to 500Kg

• 230V ac

• Duty cycle is approximately 15-20 cycles per hour

• Safe operation via obstacle detection via encoder.

• Simple programming.

Heavier Residential And Light Commercial Installations

For heavier residential and light commercial gates, the following sliding gate openers are ideal.

• For gates weighing up to 600Kg, 1000Kg and 1500Kg respectively

• 24V dc

• Solar power option

• Duty cycle is approximately 50+ cycles per hour

• Safety via obstacle detection via encoder.

• Simple panel programming and more sophisticated programming via optional Oview programmer

• Backup battery option.

• For up to 900Kg

• 230V ac

• Duty cycle is approximately 15-20 cycles per hour

• Safe operation via obstacle detection via encoder.

• Simple programming.

• For up to 900Kg

• 230V ac

• Duty cycle is approximately 15-20 cycles per hour

• Safe operation via obstacle detection via encoder.

• Simple programming.

Commercial And Industrial Installations

A commercial or industrial sliding gate system is often used much more frequently than residential sliding gates. They can be much larger and security gates usually weigh more than domestic driveway gates.

This means that these sliding gate motors must be able to deal with the weight and size of larger gates and the increased duty cycle experienced during working hours.

• For up to 1800Kg

• 230V ac

• Duty cycle is approximately 50 cycles per hour

• Safe operation via clutch pressure setting.

• Simple programming.

• For up to 1800Kg

• 400V ac

• Duty cycle is approximately 50 cycles per hour

• Safe operation via clutch pressure setting.

• Simple programming.

FAAC 884 T Gate Opener

• For up to 1800Kg

• 400V ac

• Duty cycle is approximately 50 cycles per hour

• Safe operation via clutch pressure setting.

• Simple programming.

• For up to 2500Kg

• 230V ac inverted to 3 phase

• Duty cycle is approximately 50+ cycles per hour.

• Safe operation via an encoder and current monitoring.

• Simple panel programming, and more sophisticated programming via optional Oview programmer.

V2 Hyperfor-i Gate Opener

• For a gate weighing up to 4000Kg

• 230V ac inverted to 3 phase

• Duty cycle is approximately 50+ cycles per hour

• Safe operation via encoder and current monitoring.

• Simple programming

Why You Should Come To Us

Gate Automation Supplies supports installers and automation engineers with gate openers, access control systems and components, safety equipment and all parts and accessories.

We have many years of experience in this field and provide free support for installer customers with product advice, on-site troubleshooting and safety recommendations.

Our dealings with installers around the country also means that we can recommend the right experienced and qualified installer for your job if you’re looking to have new automatic gate openers installed or you want to update or replace existing automatic gate systems.

Sliding gates are ideal in many situations where swing gates wouldn’t be appropriate or even safe. Selecting the right gate openers is a crucial part of the process.

At Gate Automation Supplies we have access to a wide range of gate motors from all leading manufacturers. We are not tied to a single manufacturer so can recommend the best motor for the job based on your unique needs, experience and budget.

If you’re looking for the right electric gate openers for your project at the right price and with free technical support, call us now on 03300 883 890 or email [email protected]

1 Comment(s)

Like to know what's the best motor for a 250kg gate and also price. Then also the track that you have on the picture

Hi, You can select any slider motor for gates up to 400Kg, I suggest you look at the RB400 kit and the Acer400 kit. For more detail please call sales on 01895 232626

Leave a Comment