Swing Gate Motors

Swing gates usually come in pairs that meet in the middle when closed. They normally open inwards to avoid obstructing or hitting anything outside the gates when opening or open. Each gate is mounted on a pillar or post on either side of the driveway.

The motors used to operate swing gates are mounted on the pillar or post and their operating arm is mounted on the gate. As the motor moves the arm, the gate is opened or closed depending on the direction the motor turns.

All swing gates obey the principles of leverage but their pivot (the hinge) is at one end. How far the gate motor arm mount is from the hinge plane will determine the force required to operate the gate. more force is required to operate the gate when the mount is closer to the hinge.

Sliding gate motors apply the same principles of operation but there are a few different types of swing gate motor as follows:

Swing Gate Hydraulic Ram Motors

Ram gate motors are quite discrete as they mostly comprise a long slim body and straight arm. The arm is pushed and pulled from the body hydraulically. As the arm is pushed from the motor, the gate opens. It then closes as the piston is retracted back into the motor housing.

Careful installation of hydraulic ram gate motors is required to avoid any pressure that prevents the arm sliding smoothly into and out of the motor body. However, the arm mounting point on the gate is a long way from the hinge so hydraulic rams are efficient in operation.

As hydraulic rams use special fluid to operate, regular inspection is required by a professional installer to make sure they aren’t leaking. If enough fluid is lost from the system, the motors will be unable to function.

Swing Gate Linear Screw Motors

Similar in appearance to hydraulic rams, linear screw gate motors are long and slim but have no obvious arm. Instead, the arm is a threaded shaft connected to a compact motor within a slim housing.

A slit in the housing’s gate side or underside that runs the length of the shaft allows a bracket threaded onto the shaft to be mounted onto the gate.

The motor turns the shaft and the threaded bracket moves along the turning threaded shaft. This opens and closes the gate depending on the direction of the shaft rotation.

As with hydraulic ram gate motors, linear screw gate motors require careful installation but they are also strong motors suitable for automating heavier or larger gates.

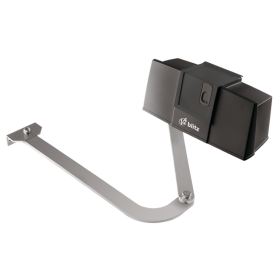

Swing Gate Articulated Arm Motors

Articulated arm motors feature a motor housing with an output shaft that usually emerges from the underside of the motor. A jointed arm is mounted on this shaft at one end and the other end is connected to the gate.

The turning motor pushes or pulls the arm and the gate opens or closes. This articulates arm closes up as the gate opens. As this can trap anything between the closing arms, gate safety needs careful consideration when installing articulated arm motors.

Although articulated arms on closing gates can present a possible danger, articulated arm motors are generally strong and do not require the intricate installation of rams and undergrounds. The arm mounting point is also far enough from the hinge to give leverage benefit.

Swing Gate Underground Motors

While rams and linear screw motors are slimline, they’re quite obvious when mounted on gates. And thanks to their larger motor housings and jointed arms, articulated arm motors are difficult to miss!

However, underground gate motors are very discrete as they’re almost totally submerged below ground level under the gates. This makes them highly popular in the UK where we have a preference for discrete gate automation.

Underground gate motors are mounted in submerged foundation boxes and the motor arm pivot forms the gate’s lower hinge. This means that the leverage benefit from the gate arm mounting point being further from the hinge is completely lost. Gates automated by underground gate motors need to be lighter or very strong motors are needed.

Additionally, undergrounds needs water drainage to prevent the motors from sitting in water for any length of time. Both these factors mean that undergrounds usually cost more to install and will need regular checking to ensure drainage holes are not blocked.

Swing Gate In-Post Motors

In-post motors are discrete motors installed within (usually) specially constructed gate posts. Arms connected to the hidden gate motors are then attached to the base of the gate.

This makes in-post motors similar in operation to undergrounds but without the requirements for drainage. They do however, need to be strong to operate gates as their arms are also mounted on the gates close to the pivot point.